NTK’s engine speed & position sensors under the spotlight

Technical features

The modern combustion powertrain is a complicated interlocking of parts that must all function individually and yet collectively to ensure the vehicle’s smooth operation. This is especially true of the crankshaft and camshaft. As an engine moves, the fuel’s combustion forces the car’s pistons straight down into the cylinder. The crankshaft then converts this linear motion into a rotation by swinging around and pushing the piston back up the cylinder. In this way, the car is propelled along. The job of the engine speed & position sensor in relation to the crankshaft, is to measure the rotational speed and position of the crankshaft, which it does by monitoring the signals sent by a toothed wheel or disk which rotates with the crankshaft. This information is readily available to car drivers in the form of the revolutions per minute or rpm figure that is characteristically displayed in a dial on their dashboard. Typically, the sensor for this purpose is installed near the crankshaft, either in or in the vicinity of the lower engine block. Sensors to monitor the crankshaft in petrol vehicles were first widely introduced in the 1980s, with their addition in diesel powertrains coinciding with common rail technology at the end of the 1990s.

The camshaft’s job is to safeguard the control of an engine’s valves. These intake and exhaust valves need to open in tandem with the requirements of the pistons and this synchronisation is absolutely vital to the engine running effectively. This is ensured by a connection between the camshaft and the crankshaft that is either made with a timing belt, timing chain or system of gears. In this way, the pistons turn the crankshaft, which turns the camshaft, which controls the valves.

NTK’s engine speed & position sensor for camshaft monitoring is used to measure the position of the camshaft and this information, together with crankshaft position and speed, is sent to the Engine Control Unit (ECU), which uses it to determine the stroke of each cylinder and therefore when to inject fuel and to define the right ignition timing. The sensor here is installed near the camshaft, in, or near, the cylinder head. These sensors are used for both petrol and diesel engines with electronic injection systems. Many modern engines have two camshafts, but not necessarily two sensors.

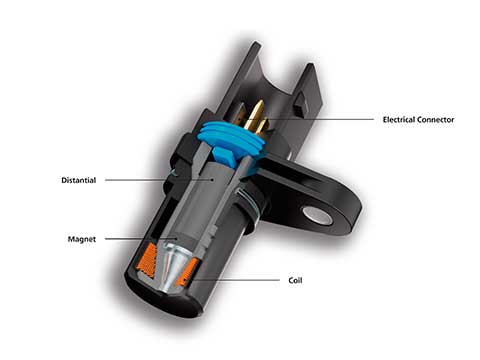

Engine speed & position sensors for observing the crankshaft work on either the inductive principle or the Hall effect principle but are not interchangeable. In contrast, sensors used to check on the camshaft generally use the Hall effect principle. NTK only offers the former. A good way to identify the brand’s sensors is by the trade numbers: "CM" shows that it is an inductive sensor, while "CH" indicates a Hall effect item.

In total, there are more than 557 part numbers available for engine speed & position sensors covering 75% of the vehicles in EMEA (source: TecDoc). With this extensive range of products, there is a replacement sensor for almost every Aftermarket application.

Possible problems with engine speed and position sensors

As with all a vehicle’s components, it is always advisable to consult the manufacturer’s instructions before deciding to either repair or replace an item. Due to the fact that engine speed & position sensors are sealed to prevent leaks and to ensure a maximum product life, problems with this component should be limited. However, occasionally water may enter the contact points or the wiring may be damaged. In many instances, the engine will not start at all in the case of the crankshaft, if the sensor here is damaged. With respect to the camshaft, it may start with difficulty, but the car will be possibly jerky when driving and either stall or misfire. As with all components, replacement will be necessary at some point. The best way to determine if the sensors are functioning properly is to check if the signal is correct. An oscilloscope should be used to determine this.

After a new engine speed & position sensor has been fitted, the ECU may have to “learn” the new location of the sensor and for this purpose a scanning tool is required to carry out this action.

Conclusion

This feature is one in a series of articles that aim to offer the reader a basic insight into the technical aspects of components offered by Niterra’s NGK Ignition Parts and NTK Vehicle Electronics brands. The next subject under the spotlight will be the Exhaust Gas Recirculation (EGR) valve, another important element of the engine’s combustion process, that is central to controlling Nitrogen Oxides (NOx) emissions produced as a by-product during the combustion process.

Previous articles in the series can be found here:

Find more insights about our car component solutions!

For further information on NTK brand’s engine speed & position sensors, please visit TekniWiki, a technical platform with interactive learning modules that is continuously updated to meet the most recent user requirements, under www.tekniwiki.com.