What is a oxygen sensor (o2 sensor)?

What is a oxygen sensor (o2 sensor)?

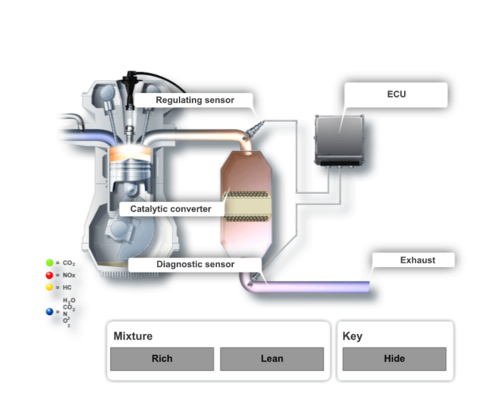

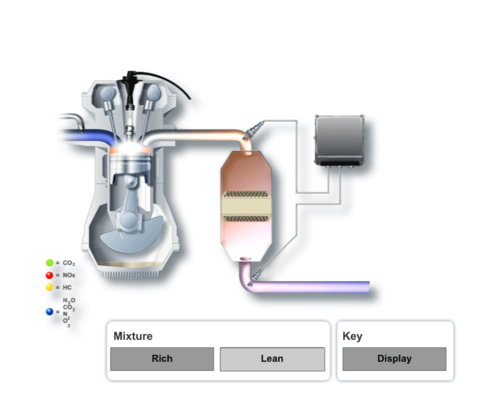

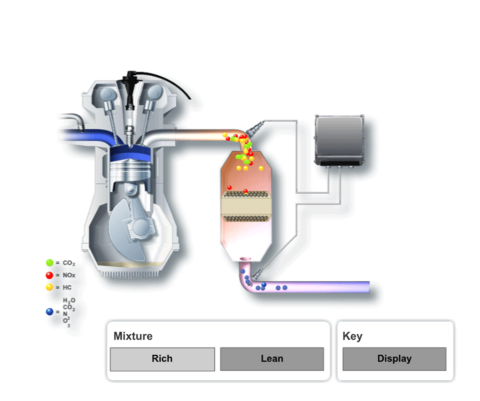

Also known as a “lambda sensor”, an oxygen sensor ensures ideal conditions for the catalytic converter by providing constant measurement of the air-fuel ratio. The optimum air to fuel mixture for an internal combustion engine is one that has a ratio of 14.7-part air to 1-part fuel: This specific air-fuel combination is called ‘lambda’. This ratio, however, isn’t automatically guaranteed, which is the reason why oxygen sensors play such an important role.

Normally located in a motorcycle’s exhaust system (before, or before and after the catalytic converter), an oxygen sensor measures the percentage of oxygen in the exhaust system. It then reports the information back to the motorcycle’s electronic control unit (ECU).

Often, the air-fuel mixture is either too rich or too lean for the catalyst converter to do its job properly. If the mixture is too rich, the exhaust system contains not enough oxygen. Vice-versa, if the mixture is too lean, there is too much oxygen present. In both cases, ultimately, an efficient function of the catalyst is not possible.

To counter this, the oxygen sensor relays its findings to the ECU which then adjusts the air-fuel mixture as close to the 14.7 ratio as possible. This results in more efficient combustion, which not only benefits the environment by reducing emissions, but also bank balances due to fuel savings and less engine wear and tear.

Bad oxygen sensor symptoms

A bad or failing oxygen sensor can be due to many reasons. An oxygen sensor needs to be replaced due to general deterioration over time, but other avoidable factors can lead to a sensor needing to be replaced sooner than originally planned.

Common causes of failure in oxygen sensors occur when it comes into contact with:

-

Fuel Additives: Oxygen sensors can be destroyed by fuel additives which are sometimes included in fuel or are added separately by the driver. It can, therefore, be recommended to avoid using fuel additives or fuels containing them.

-

Silicone: Contact with silicone closes the porous ceramic surface of the sensor. This prevents ions from transferring, resulting in voltage not being generated. Penetrating oil and engine grease are common sources of silicone contamination. A sure way to prevent this type of contamination is to use silicone-free products such as oxygen sensor grease. All NTK Vehicle Electronics sensors, moreover, are sold in sealed, plastic packaging, eliminating the possibility of silicone contamination.

-

Carbon Deposits: Deposits can appear on both the sensor’s protective cap and element. This will cause the sensor to become lazy and ultimately fail. The source of the excess carbon deposits needs to be identified or the new sensor will encounter the same problem.

O2 sensor replacement

Watch our video on how to correctly replace a oxygen sensor on a car:

O2 sensor replacement on a motorcycle

Be it contamination or simply age, the installation of a new oxygen sensor is often a necessary maintenance step for motorcyclists. Although the sensor plays a very important role, its replacement is an easy procedure. While it is recommended to seek the help of a professional if issues such as thread seizing occur, the replacement of an oxygen sensor, generally, is something that can often be carried out by the rider themselves.

Signs that your motorbike is due a replacement include the “check engine light” coming on, bad fuel mileage, a misfiring engine and irregular engine idling. In the case of motorcycle enthusiast Valerie Hoppe, Specialist Brand Communication Aftermarket at NGK SPARK PLUG EUROPE GmbH, who replaced the oxygen sensor on her motorcycle without any professional assistance, her motorcycle showed an error message referencing the oxygen sensor.

“The price of getting it replaced by a professional and the relatively long distance to a trusted workshop were the main reasons I decided to do it myself”, she says. Although not a “hobby mechanic”, Valerie wasn’t daunted by having to carry out the replacement on her own. “I have tinkered with my 125cc since I was 16 so I was confident I could do it”, she says.

“It’s very quick and simple. All you have to do is remove the plug, unscrew the sensor, screw in a new sensor, put the plug back on and hey presto, you’ve got a fully functioning oxygen sensor again”, she proudly says. Considering both the emissions and engine performance benefits, as well as how simple it is to replace it, the oxygen sensor plays a heroic role in guaranteeing easy riding.